MACHINES

Beta

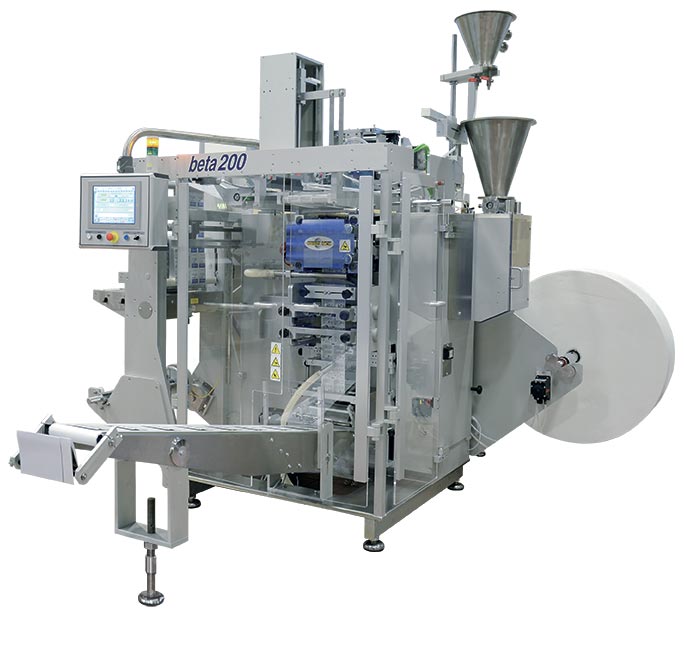

Automatic sachet machine “Beta 200″ range, operated by intermittent motion

New and advanced technologies characterize the “Beta 200″ sachet machines in terms of quality, easy size change and simple, easy cleaning access. Together, these features make the machines particularly suitable for the cosmetic and pharmaceutical sectors. High quality and aesthetically first class sachets are produced as the seals are made during the standstill phase.

TYPES OF PACKAGING

IDEAL FOR THE PACKAGING OF

TECHNICAL DATA

Beta 200

- Width: min 40 mm; max 200 mm

- Length: min 50 mm; max 170 mm

- Production output: up to 160 sachets/min, depending on the type of product features of the wrapping material and n. of lanes

- Dose: from 0,1 to 100 cc

- N. lanes: from 1 to 2

- Maximum film reel width: 400 mm

- External film reel diameter: 800 mm

- External wipe reel diameter: 1.200 mm

Beta 360

- Width: min 40 mm; max 150 mm

- Length: min 50 mm; max 160 mm

- Production output: up to 450 sachets/min, depending on the type of product features of the wrapping material and n. of lanes

- Dose: from 0,1 to 100 cc

- N. lanes: from 3 to 6

- Maximum film reel width: 1.000 mm

- External film reel diameter: 800 mm

- External wipe reel diameter: 1.200 mm

Beta 500

- Width: min 40 mm; max 150 mm

- Length: min 50 mm; max 160 mm

- Production output: up to 800 sachets/min, depending on the type of product features of the wrapping material and n. of lanes

- Dose: from 0,1 to 100 cc

- N. lanes: from 6 to 10

- Maximum film reel width: 1.000 mm

- External film reel diameter: 800 mm

- External wipe reel diameter: 1.200 mm

Main technical features and available accessories

- Dosers for: powders / granules / pastes / liquids / wet wipes

- Machine frame made completely of aluminium and stainless steel

- Ability to store on work programs

- Coding systems for required data on sachets: Embossed or Ink jet with various data programmable by touch screen

- Film unwinding activated by synchronized servomotors (brushless), constant film tension and automatic reel alignment

- Orderly collation of the filled sachets in the required pre-programmed number

- N-line check-weighing of the sachets, with automatic reject of sachets out tolerance and auto-regulation of the doser (trend control feed-back)

- Conformity with the GMP criteria (ease of cleaning) and with CE/FDA regulations

- Monitoring via modem for tele-assistance

- Synchronised brushless servo-motors activate the movements, by adjustment and memory via touch screen of all the machine functions (sachet size, dose, speed, temperature, etc.)

DOSING SYSTEMS

- Doser with Pistons

- Gravimetric Doser

- DAuger Doser

- Wet Wipe Folding Group