MACHINES

Kappa

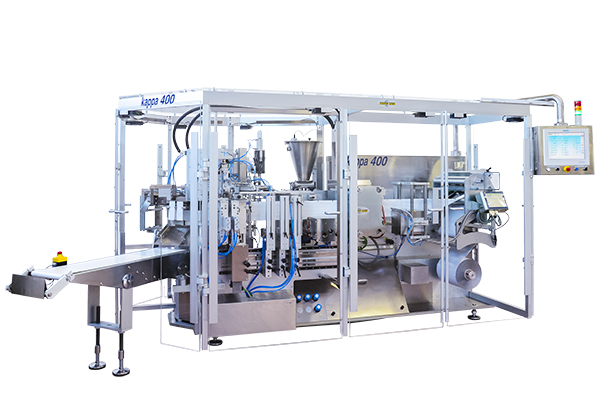

Horizontal sachet machine “Kappa 400-620″ range, operated by intermittent motion

New and advanced technologies characterize the “Kappa 620″ sachet machines in terms of quality, easy size group change and simple, easy access for cleaning (conforming to cGMP criteria). Together, these features make the machines particularly suitable for the cosmetic, pharmaceutical and also food sectors.

The on line sachet forming and the subsequent filling in carousel on 3 independent stations guarantee aesthetically faultless packaging with the possibility of three-side, four-side sealed and doypack (stand up) style sachets, and production output up to 11,000 sachets/hour.

The implementation of synchronised brushless servo-motors coupled with patented systems allow to produce a wide range of sachet formats on one and two lanes and their setting by colour touch screen monitor 12″ with storage of up to 30 working programs.

The machines are suitable for packing of pastes and/or liquids, granules and/or powders, solids with special applicators for caps, zip, drinking straws, etc.

TYPES OF PACKAGING

IDEAL FOR THE PACKAGING OF

TECHNICAL DATA

Kappa 400

- Width: min 50 mm; max 180 mm

Length: min 50 mm; max 200 mm - Production output: up to 140 sachets/min, depending on the type of product, characteristics of the wrapping material and n. of lanes

- Maximum film reel width: 360 mm

| Range of sachet formats | Sachet size range | Maximum reel wide | |||

|---|---|---|---|---|---|

|

Single Bag | A min 50,0 | A max 200,0 | H max 180,0 | max 360,0 |

|

Double bag with perforation | A min 50,0 | A max 110,0 | H max 180,0 | max 360,0 |

|

Two bags | A min 50,0 | A max 110,0 | H max 180,0 | max 360,0 |

Kappa 620

- Width: min 50 mm; max 240 mm

Length: min 50 mm; max 240 mm - Production output: up to 140 sachets/min, depending on the type of product, characteristics of the wrapping material and n. of lanes

- Maximum film reel width: 600 mm

| Range of sachet formats | Sachet size range | Maximum reel wide | |||

|---|---|---|---|---|---|

|

Single Bag | A min 50,0 | A max 240,0 | H max 240,0 | max 480,0 |

|

Double bag with perforation | A min 50,0 | A max 125,0 | H max 240,0 | max 480,0 |

|

Two bags | A min 50,0 | A max 125,0 | H max 240,0 | max 480,0 |

|

Doypack “Stand up” | A min 50,0 | A max 240,0 | H max 240,0 | max 600,0 |

|

Doypack “Stand up” | A min 50,0 | A max 125,0 | H max 240,0 | max 600,0 |

Main technical features and available accessories

- Dosers for: powders / granules / pastes / liquids / feeder plug

- Ability to store on work programs

- Coding systems for required data on sachets: Embossed or Ink jet with various data programmable by touch screen

- Film unwinding activated by synchronized servomotors (brushless), constant film tension

- Orderly collation of the filled sachets in the required pre-programmed number

- Monitoring via modem for tele-assistance

- Synchronised brushless servo-motors activate the movements, by adjustment and memory via touch screen of all the machine functions (sachet size, dose, speed, temperature, etc.)

DOSING SYSTEMS

- Doser with Pistons

- Gravimetric Doser

- Auger Doser

- Plug Feeder